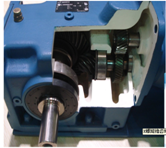

GEMCO pellet mill is characterized by high efficiency, large output capacity, low power consumption, and gear transmission structure that has long service life.

Once you have purchased your desirable pellet mill, it is proper maintenance that will make sure that it works as you’ve required. The key areas of maintenance are grease, oil, gearbox, main axis, and roller and die condition.

You should always keep in mind that when making wood pellets and operating wood pellet machine, the temperatures you are dealing with will be higher than other pellet mills. Therefore, this means that you need to use higher quality oils in the gearbox and also higher quality grease in the rollers and die. Serious damage can be done to the gear box if the condition of the oil and level of oil is not given the attention it deserves. Likewise for the grease in the rollers and the bearings on the drive shaft for the die. Extreme temperature grease is required and in some cases automated grease systems are used to make sure the rollers are always properly greased.

|

NO.

|

Lubrication part

|

Oil type

|

Period of lubrication

|

Period of oil change

|

|

1

|

roller

|

lithium base grease

|

twice per shift

|

|

|

2

|

main axis

|

lithium base grease

|

once per shift

|

|

|

3

|

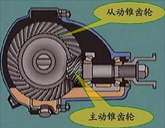

gear box

|

hypoid gear oil

|

up to the set site at the first time

|

six months

|

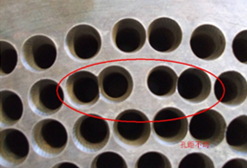

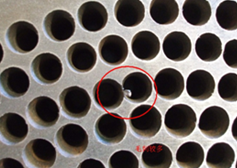

1. Grinding before use. Before initial operation, make sure the gearbox is added with oil and bearings are properly lubricated according to the above chart. Because the mould pinch roller of pellet mills is mostly a heat treatment, after workstages of planning, drilling, milling, and quenching. There are probably many burr inner bore or surface, so a new pellet mill before using must be reasonably ground fully.

2. Before starting the machine, check whether the roller cover bolts become flexible, to prevent nut from falling down into the material, which cause the damage accident of compression roller.

3. Only after feeding you can start the machine, operating without raw material is forbidden. When the materials pressing is coming to an end, put a little bran mixed with edible oil in the machine and close down after suppression of 20-50 seconds, make die hole full of fuel, so that next time feed pellet mill can commissioning run as soon as possible, this can both maintain mold and save time. Loose pressure wheel to adjust screw and remove residual material after closing down.

4. You should never touch the pressing roller and die with hands or metal tools. You can use crabstick to stir when necessary.

5. Monthly check whether the electric equipment is in good condition or whether the wire is aged.

6. Use the pellet mill with clutch, before starting the diesel engine, make clutch separated. After starting the diesel engine, make clutch close slowly, and often check tightness of leather belt, check belt to prevent lower output, belt skid.

7. If you find clamping and unusual noise, you should stop the machine immediately. Restart the pellet mill after solving the problem.

8. Corrosion should avoid. As the dies are made of carbon steel, and during processing heat is produced and moisture is released from the raw material. Once the pellet mill has stopped processing and there is no material flow this moisture will start the attack the surface of the metal. Basically it will start to make the surface of the holes rough and this can lead to frequent blockages. Sand, oil and bran can be used.

Moreover, if you have any problem that is beyond your handling range, you can contact us ASAP. We are always at your service and we will try our best to help you!